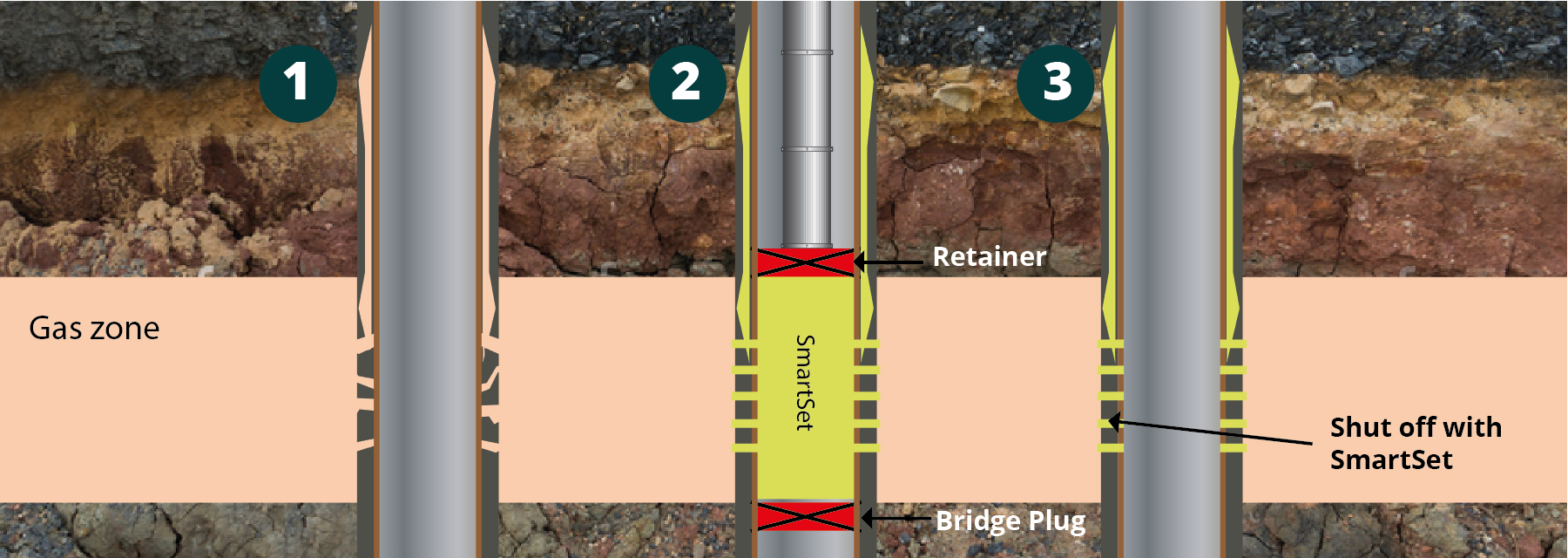

1

Problem

Gas migration between production and

surface casing.

2

Solution

- Isolate zone to be perforated.

- Perforate at top of gas zone.

-

Squeeze SmartSet through perforations

and up micro annulus.

3

Result

Surface vent gas flow eliminated.

Drill out and pressure test if desired.

Perforations shut off with SmartSet.